STRATOCONCEPTION process

Stratoconception® is the additive manufacturing process that enables the production of large and complex shaped parts in multiple materials

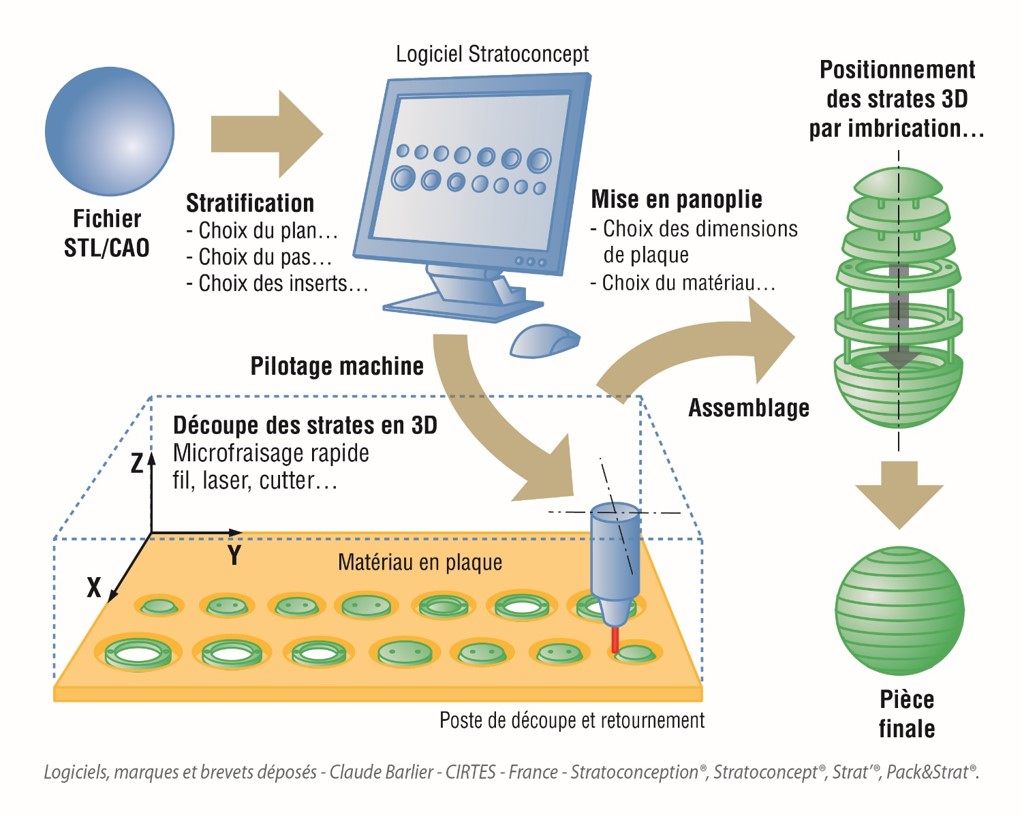

After research work initiated by Professor Claude Barlier, the standardized process (ISO 17296-2) of additive manufacturing, Stratoconception® is used to manufacture parts layer by layer from 3D files.

The Stratoconcept® PRO software allows to break down an object into a series of strata then manufactured by micro-milling or other cutting means (laser, cutter, hot wire, …) in any plate material.

These strata are then assembled together with the help of positioning elements to obtain a precise and resistant part.

STRATOCONCEPTION applications

The fields of application of the Stratoconception® process are very varied for wood, polymer or metal parts, for medium, large and even very large parts.

The process applies :

- To prototyping, in all sectors of activity for the realization of models, aesthetic, technological or functional prototypes.

- At the rapid tooling for all industrial processes especially foundry, the shaping of composite materials, thermoforming, extrusion blow molding, the shaping of concrete, …

- To the production of direct parts for art, design, decoration, furniture, furnishings, POS, … but also the emerging field of industrial maintenance and its supply-chain.

STRATOCONCEPTION offer

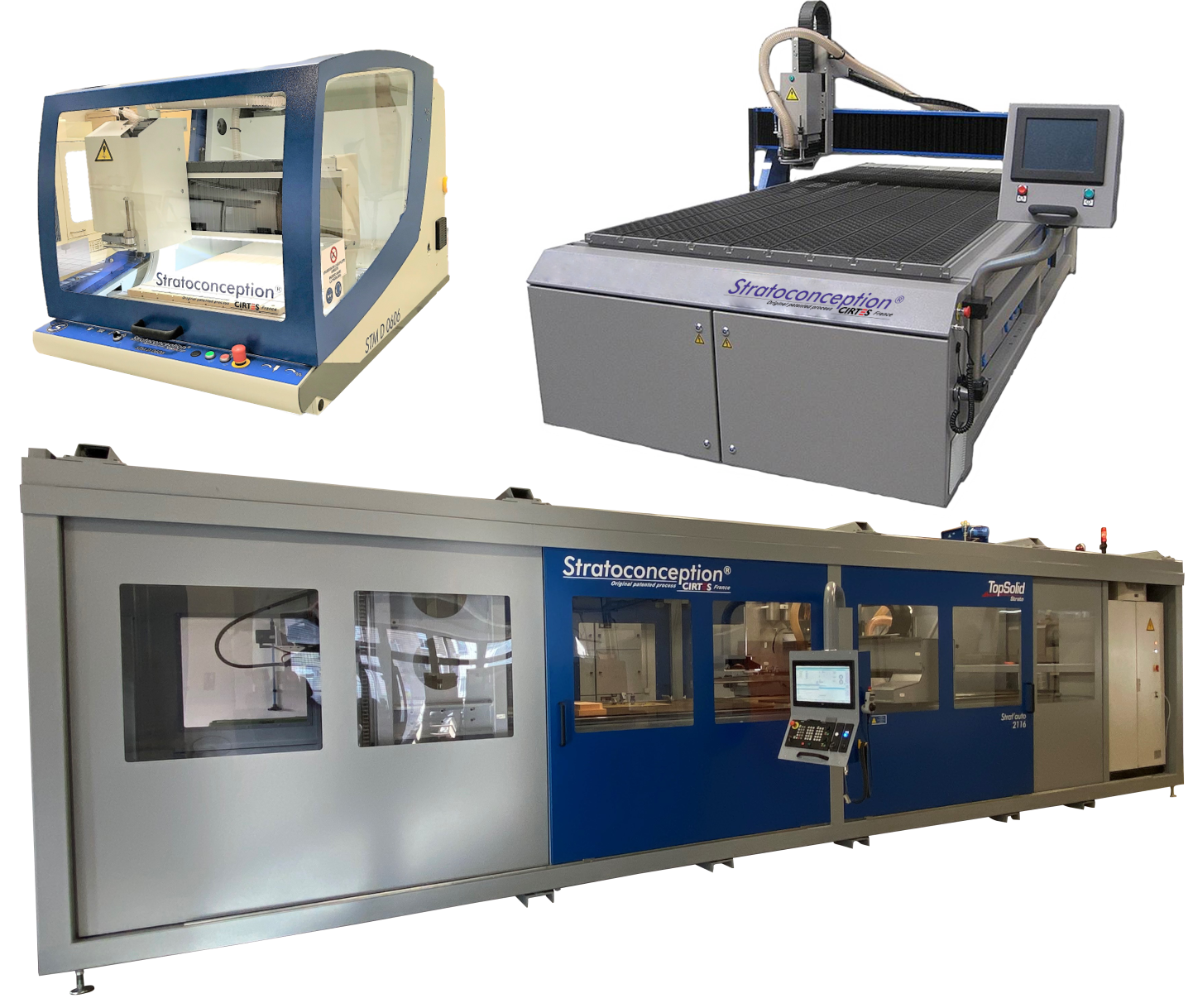

Two options: installing a solution or on-demand service