ACTARUS process

Machining Monitoring with the ACTARUS® System

The patented Actarus® process

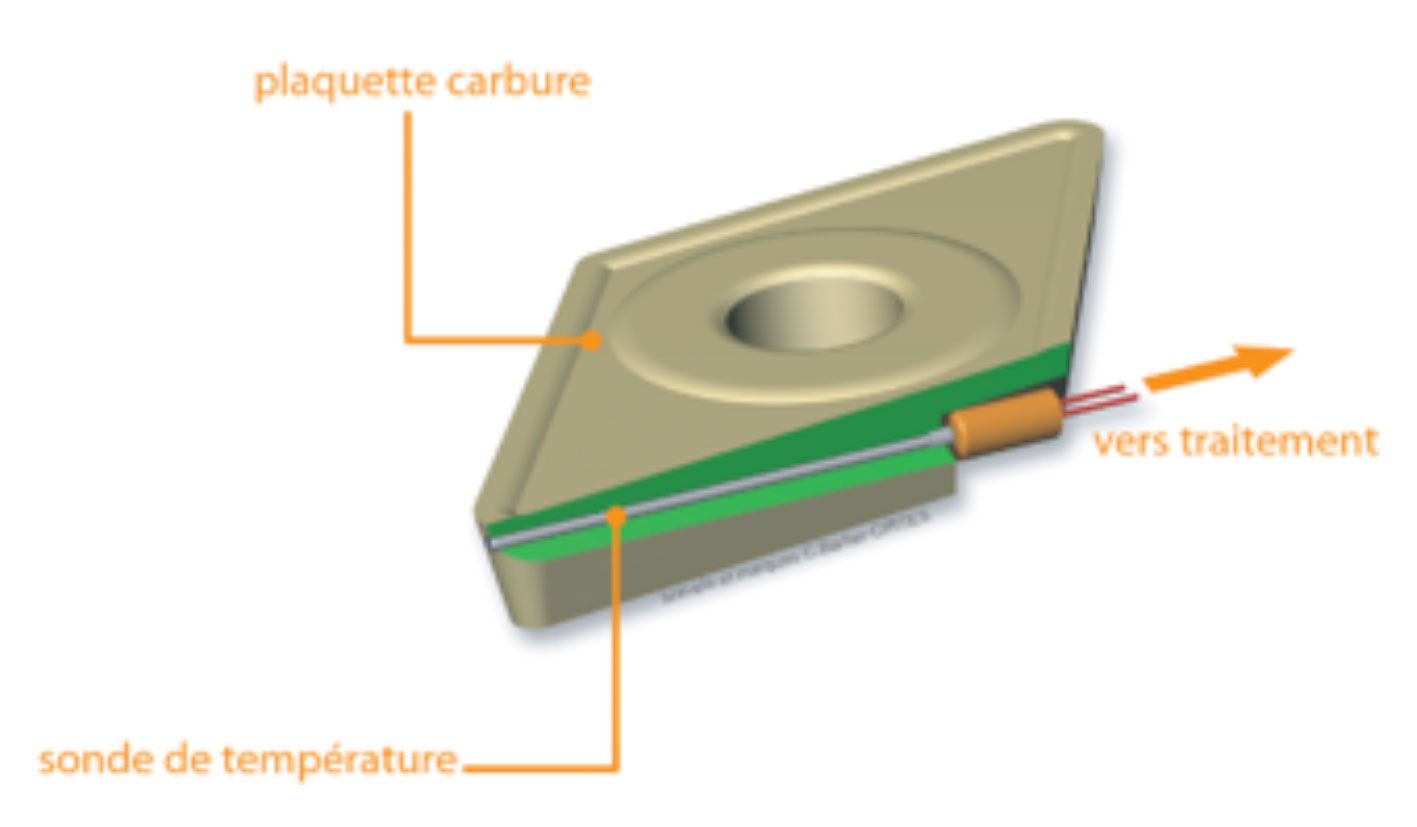

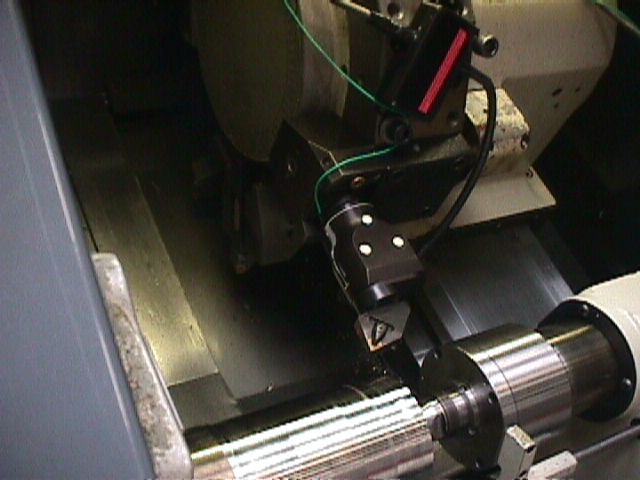

Among the monitoring systems currently available on the market, the patented Actarus® process is the only one that allows temperature to be measured directly at the heart of the cutting process: the measurement point is located on average, depending on the configurations adopted, a few hundredths of a millimeter directly under the cutting edge, at the interface between the workpiece and the tool and/or the tool chip.

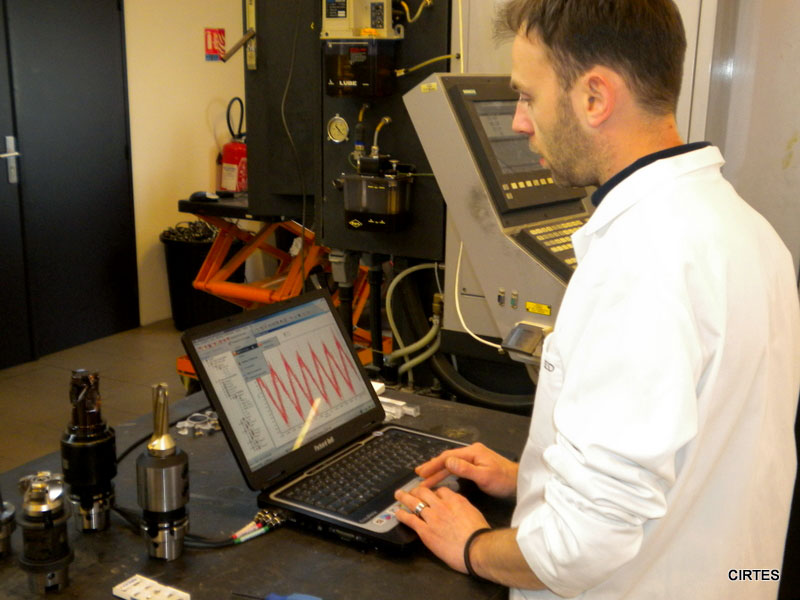

The Actarus® system with the TWS Suite® software, help to eliminate tool breakage, optimize cutting conditions, manage wear and tool life.

ACTARUS Applications

- protection of the cutting process by reducing tool breakage and machine stoppages,

- continuous monitoring of draft wear for optimization of tool life and management of tool changes,

- optimization of cutting parameters for a tool-material pair (Machining exotic materials, hard turning,

- increasing the chip flow, …),

- the choice of cutting fluid and optimization of the coolant system (qualification of lubricants and control systems),

- the study of cutting phenomena (added edges, particular wear, …).

ACTARUS offer

Two options: on-site studies and testing or installation of a solution