FABRICATION ADDITIVE - USINAGE AVANCÉ

CIRTES SA est une société labellisée Structure de Recherche Contractuelle (SRC). Située au cœur du bassin industriel de Saint-Dié-des-Vosges depuis 1991, CIRTES possède également un établissement à Carmaux, dans le Sud-Ouest de la France. A partir de ses spécialités brevetées, la Fabrication Additive par Stratoconception®, l’Emballage Rapide 3D Pack&Strat® et la Surveillance de l’Usinage Actarus®, CIRTES a vocation à développer des contrats industriels de Recherche & Développement, à fabriquer des maquettes et outillages et à commercialiser des solutions logicielles et des machines associées.

Présentation & Historique

Depuis 1991, CIRTES développe et diffuse des procédés issus de ses travaux de recherche en Fabrication Additive et Usinage Avancé.

Historique

Créateur d’innovations depuis 1991

Pole VirtuReal

De la Recherche à l'industrie

Equipe

Des compétences au service de l’Industrie 4.0

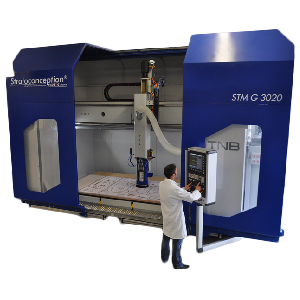

Equipements

Une plate-forme de pointe pour l’innovation

Références

Des partenariats solides

CIRTES A L'ORIGINE DU PÔLE VIRTUREAL

VirtuReaL est le pôle international au service du Développement Rapide de Produit

Nos technologies

Le savoir-faire de CIRTES s’articule autour de 3 procédés majeurs brevetés

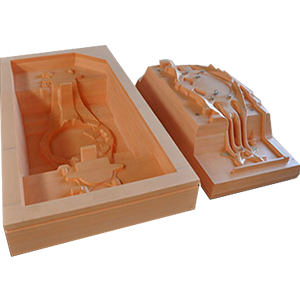

Stratoconception®

La Fabrication Additive mutli-matériaux et grandes dimensions.

Pack&Strat®

L’emballage 3D ultraprotecteur.

Actarus®

La maitrise de l’usinage par le monitoring.

DES MOYENS AU SERVICE DES PROFESSIONNELS

CIRTES dispose d’équipements de pointe au service de ses clients

Notre offre

CIRTES propose un ensemble de solutions développées par ses équipes.

Produits

Logiciels, machines et équipements

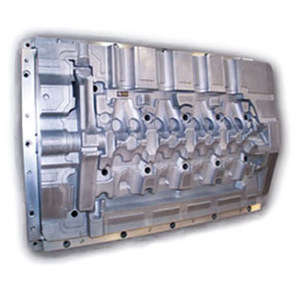

Prestation

Fabrication de maquettes, outillages

Essais d’usinage

R&D / Expertise

Recherche contractuelle et expertise métier

Ingénerie

Intégration de la Fabrication Additive et de la Surveillance de l’Usinage

Développement

Développement d’applicatifs métier sur mesure

Formation

Formations sur la Fabrication Additive et sur l’Usinage Avancé